Environment

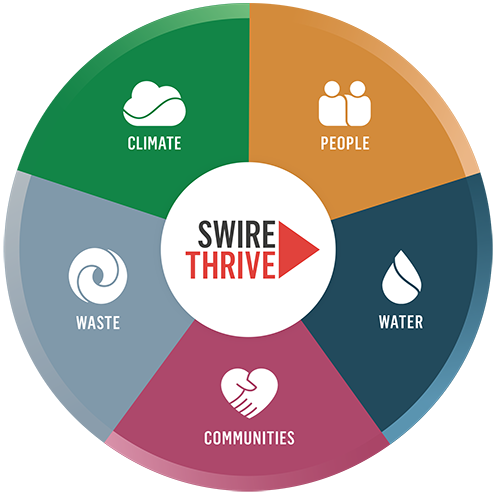

We believe that business growth should not come at the expense of the environment. This is why in 2016 Swire introduced "SwireTHRIVE", a new group-wide environmental sustainability strategy which will have an impact on every part of Swire's operations. With the notion that "When we help the world in which we operate to thrive, so do we", the "SwireTHRIVE" strategy comprises six key target areas for improvement that have been identified as being material to our businesses. They are: Carbon, Waste, Water, Sustainable Materials, Biodiversity and Climate Resilience. These goals are due for delivery by 2030, with initial emphasis on 2020 milestones.

In order to achieve these objectives, we encourage practical innovation, and invest in technologies and improvement processes that help reduce environmental impacts and generate long-term growth. We strive towards the highest standards of operational efficiency.